John Deere約翰迪爾強鹿柴油發動機拆卸安裝技術手冊

詳細描述

John Deere約翰迪爾強鹿柴油發動機拆卸安裝技術手冊

In some applications, it may be necessary to remove

engine from machine to service cylinder head. Refer to

your Machine Technical Manual for engine removal

procedure.

CAUTION: After operating engine, allow exhaustsystem to cool before working on engine.Do NOT drain coolant until the coolanttemperature is below operating temperature.Remove radiator filler cap only when the cap iscool enough to touch with bare hands. Slowlyloosen cap to first stop to relieve pressurebefore removing completely.

1. Drain engine oil and coolant.

2. Remove air intake line and intake line betweenturbocharger and intake manifold.

3. Remove exhaust line from turbocharger.

NOTE: Turbocharger may be removed from engine whileassembled to exhaust manifold, if desired.

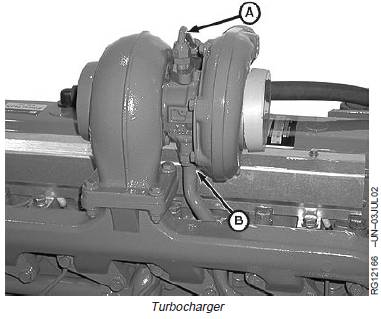

4. On turbocharged engines, disconnect turbocharger oilinlet line (A) and oil drain line (B). Removeturbocharger from exhaust manifold. (See REMOVETURBOCHARGER in Group 080.)

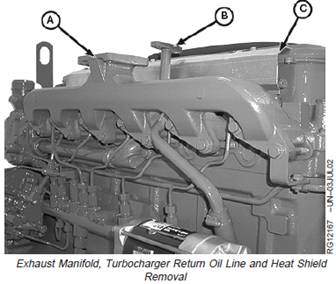

5. Remove exhaust manifold (A).

6. Remove turbocharger oil drain line (B) and heat shield(C).

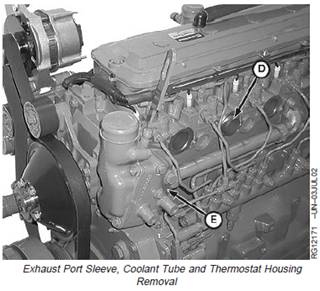

7. Remove sleeve (D) from each exhaust port.

8. Remove thermostat housing (E), coolant manifold andside port. See REMOVE AND INSTALL COOLANT

MANIFOLD, THERMOSTATS AND SIDE PORT(FOUR-VALVE HEAD) in Group 070.

A—Exhaust Manifold

B—Turbocharger Oil Drain Line

C—Heat Shield

D—Sleeve

E—Thermostat Housing

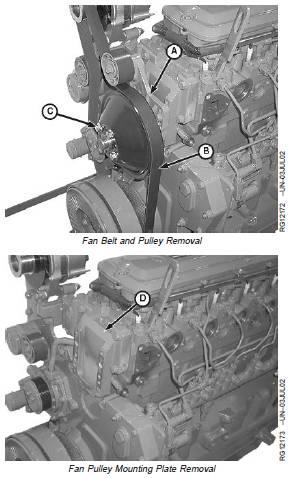

9. Loosen cap screws (C), remove fan belt (B) andremove cap screws (C) with pulley.

10. Remove bracket (A) from engine.

11. Remove plate (D) from engine.

A—Bracket

B—Fan Belt

C—Cap Screws (4 used)

D—Plate

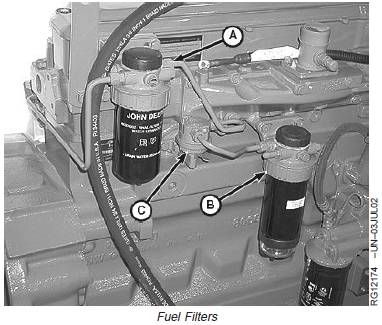

12. Remove fuel filters (A) and (B) and mounting bracketsas required.

13. Remove fuel supply pump (C). Inspect face of fuelsupply pump lever for wear. If worn flat or concave,replace fuel supply pump.

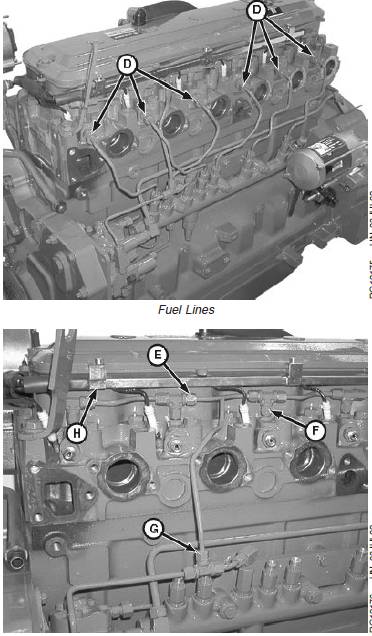

14. Remove fuel delivery lines (D).

15. Remove glow plug harness with rail (H) from engine.

16. Disconnect fuel leak-off line nut (G) and tee fitting nut(F) at each tee fitting.

17. Remove fuel leak-off line assembly (E) from engine.

18. Remove alternator, if desired. (See REMOVE ANDINSTALL ALTERNATOR in Group 100.)

A—Final Fuel Filter

B—Primary Fuel Filter/Water Separator

C—Fuel Supply Pump

D—Fuel Delivery Line

E—Fuel Leak-Off Line Assembly

F—Tee Fitting Nut

G—Fuel Leak-Off Line Nut

H—Glow Plug Harness Rail

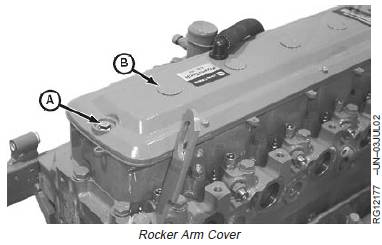

19. Remove button plugs (B) from rocker arm cover.

20. Remove cap screws with O-rings (A) and rocker armcover.

A—Cap Screw with O-ring

B—Button Plug

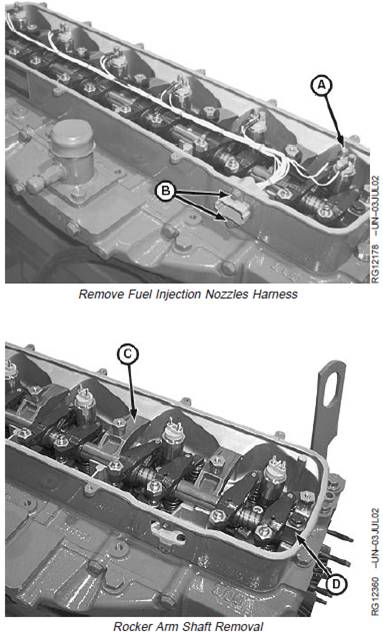

21. Remove two cap screws (B) and nut (A) on all fuelinjectors. Remove fuel injection nozzle harness.NOTE: Loosen all rocker arm adjusting screws prior toremoving assembly.

22. Remove both end clamclamps (D), clamps (C) and rockerarm shaft assembly.

A—Nut

B—Cap Screw (2 used)

C—Clamp

D—End Clamp

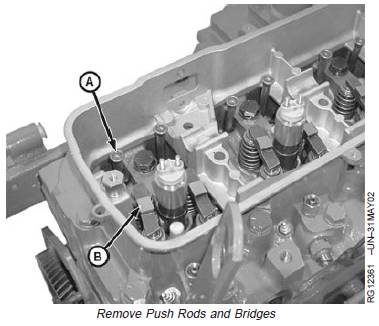

23. Remove all push rods (A) and identify for reassemblyin the same location. Clean and inspect push rods.

24. Remove all bridges (B) and identify for reassembly inthe same location.

A—Push Rod

B—Bridge

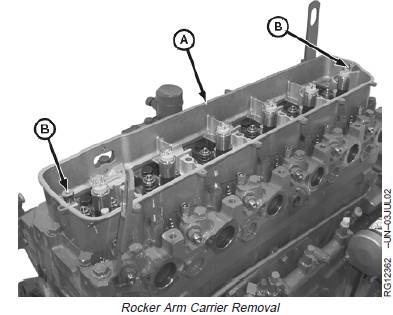

25. Remove screws (B) and rocker arm carrier (A).

A—Rocker Arm Carrier

B—Screw

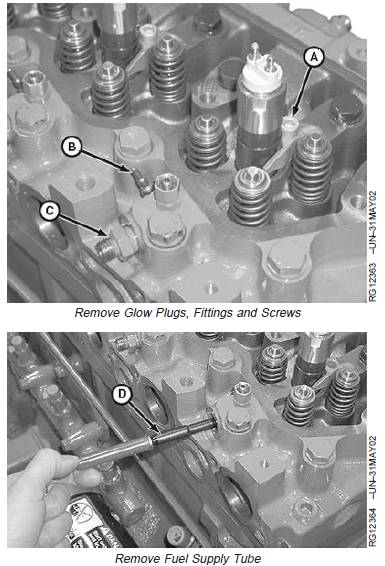

26. Remove glow plug (B), fitting (C) and screw (A) fromeach cylinder.

27. Remove fuel supply tube (D) using a magnet.

28. Remove fuel injector with clamp using JDG1652Injector Nozzle Removal Tool (E).

A—Screw

B—Glow Plug

C—Fitting

D—Fuel Supply Tube

E—JDG1652 Injector Nozzle Removal Tool

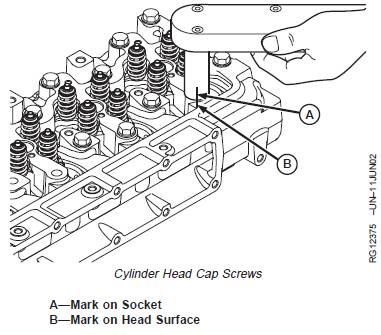

29. If a cylinder head gasket failure has occurred, checkand record torque on each cylinder head cap screwbefore removing.To check cylinder head cap screw torque:

a. Make a reference mark (in-line) on socket (A) andcylinder head surface (B).

b. Loosen cap screw at least 1/2 turn.

c. Retighten cap screw (using a torque wrench) untilreference marks align. Record torque.

30. Remove all cylinder head cap screws.

IMPORTANT: DO NOT use screwdrivers or pry barsbetween cylinder block and head toloosen head gasket seal. Screwdriversor pry bars can damage cylinder headand block gasket surfaces.

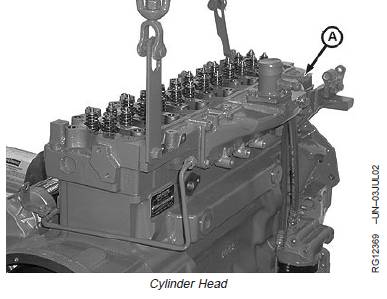

31. Lift cylinder head (A) from block. If cylinder headsticks, use a soft hammer to tap cylinder head.

A—Cylinder Head

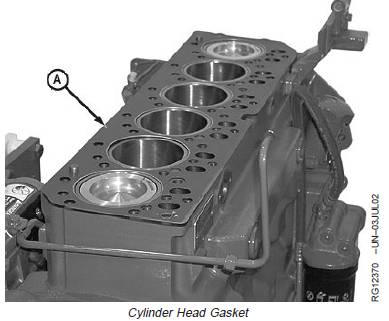

32. Remove cylinder head gasket (A). Inspect for possibleoil, coolant, or combustion chamber leaks. Also,check for evidence of incorrect head gasket beingused.

NOTE: Do not rotate crankshaft with cylinder headremoved unless cylinder liners are secured withcap screws and large flat washers. (SeeMEASURE CYLINDER LINER STANDOUT[HEIGHT ABOVE BLOCK], later in this group.)

A—Head Gasket

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文

中文 Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韓國

韓國 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska